Bagru Block Printing

-

Original price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| /

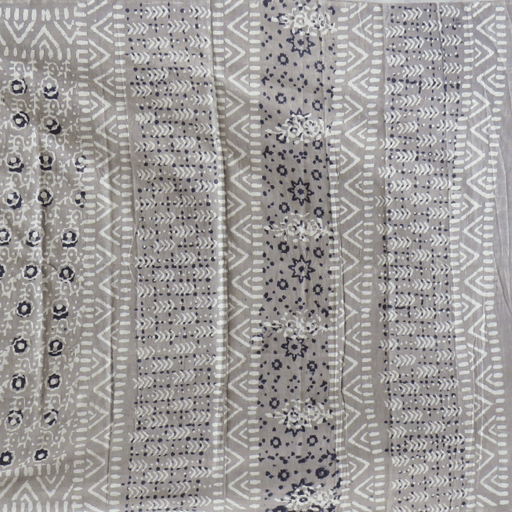

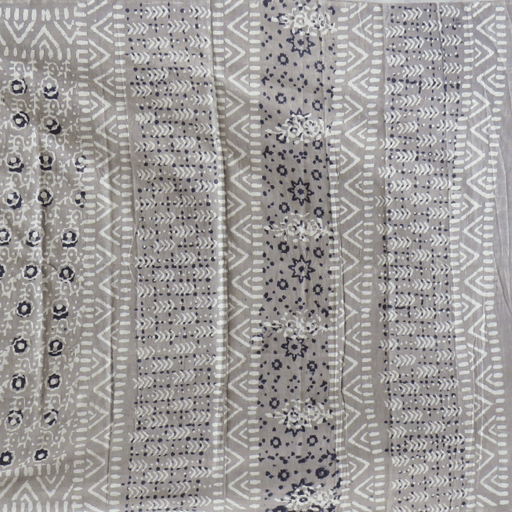

Original price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| /Grey Hand Block Print Mulmul Saree

Bhagchand Chhipa

Ready To ShipNo reviewsThis beautiful saree comes from Bagru in Rajasthan, one of India's oldest surviving block-printing cluster. Founded by members of Chhipas (stampers...

View full detailsOriginal price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| / -

Original price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| /

Original price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| /Mehendi Green Hand Block printed sarees with Diamond Motiff

Bhagchand Chhipa

Ready To ShipNo reviewsThis beautiful saree comes from Bagru in Rajasthan, one of India's oldest surviving block-printing cluster. Founded by members of Chhipas (stampers...

View full detailsOriginal price ₹1,360.00 - Original price ₹1,360.00Original price ₹1,360.00₹1,360.00₹1,360.00 - ₹1,360.00Current price ₹1,360.00| /

Bagru – Rajasthan's Block Printing Heritage

The small town of Bagru, some 35 km away from Jaipur, is an integral part of India’s rich block printing heritage. Along with Indian spices, it was the domestic hand woven, stitched and printed textiles that drew admirers from across the globe. Bagru is an internationally-renowned hub for beautiful Dabu and Syahi Begar block print textiles. These block print styles are believed to have emerged some 450 years ago, and this particular cluster developed when members of Chhipas (stampers or printers) community resettled here. Traditional Bagru textiles were characterised by the use of vibrant colours derived from natural sources, the motifs deeply rooted in nature and prevailing social structures as well as the mud-resist and mordant dyeing techniques. Centuries later, the Chhipa Mohalla in Bagru continues to thrive as a vibrant block printing hub, that churns out fabrics, safa turbans, sarees, scarves, shawls, kurtas, wall hangings as well as home furnishing items like bed covers and quilts.

History, Origin and Popular Styles of Bagru Block Printing

One theory regarding the origin of Chhipa Mohalla suggests that it was the Thakur of the town who invited Chhipas from Gujarat and other parts of Rajasthan to Bagru, in order to establish a block printing cluster here. Another theory states that the Chhipas migrated to Bagru from Alwar when Maharaja Sawai Jai Singh II established the new capital city of Jaipur. What is clear from historical references is that the Chhipa Mohalla set up on the Sanjaria riverside grew under royal and noble patronage to become a crafting centre of excellence, famous for beautiful block printed safas, lugdis, angochas and rezais.

The soil around the river was essential to this settlement as it constituted as the main ingredient of the pre-printing process. The cloth was smeared with clay derived from the riverbanks and dipped in turmeric water to get the beige coloured base synonymous with Bagru prints. After drying the fabric, it was stamped with beautiful designs using wooden blocks and mostly earthy-toned dyes made from natural sources. The reds were prepared from fitkari (alum), madder root, and babul gond (a natural gum paste), the syahi for blacks was prepared using rusted scrap iron and jaggery, and the blues were derived from indigo fermented with Castoria seeds. Coriander sprigs, pomegranate rinds, and rose petals entered the fray to create the more vibrant colours.

Dabu and Syahi-Begar are the two most famous styles associated with Bagru Block Printing. Syahi-Begar or alizarin printing is a type of mordant-based hand block printing technique with patterns in black and red. Dabu prints follow a resist-dyeing technique where a paste made with mud, gum, lime and white chaff is applied on parts of the block-printed fabric to be protected from the dyes. Once the mixture dries up, the fabric is dipped into the dyeing vat, followed by a wash to remove the excess dye and paste. With some painstaking effort, the Chippas at Bagru have managed to preserve the heritage and crafting traditions close to their original form and significantly raised the stature of the cluster.

Tools, Steps and Processes of Bagru Block Printing

One of the main tools in the entire process are the blocks, with each one requiring up to 15 days to perfect. Skilled craftsmen use small chisels to hand-carve the blocks, mostly out of seasoned teak wood. Three kinds of blocks are used for printing. The one used for the background is known as the Gadh, the one used for outlining is called Rekh and finally the one used to fill in the colours is called Datta. Each block has a wooden handle and two to three cylindrical holes drilled into it, to allow release of excess printing paste. The new blocks are soaked in oil for 1-2 weeks to soften the grains in the timber. In some cases, thin sheets of metal are hammered over the carved wood.

To prepare the fabric, it is first washed clean of starch and any other impurities. It is then soft-bleached in case the natural grey colour is not desired. The printers often follow the traditional method of incorporating the use of fuller’s earth and turmeric water to achieve the desired base colour. After bleaching, if any tie-dyeing is required, it is done at this stage. Thereafter, excess dyes are washed off and the cloth is left out to dry. Once dry, it is ready to be imprinted.

The fabric is stretched out on a table and depending on the intricacies of the design, multiple printers may work simultaneously on the same piece. Each printer is accompanied by small trolleys with racks. The blocks are placed in the lower shelf while the upper ones carry the dyes. The blocks are dipped into the dye and pressed firmly on to the fabric to ensure a good impression is registered. A point on the block serves as a guide for the repeat impression, to ensure precision and continuity in the motifs. The outline printer leads the process and is normally the more experienced one. The more the number of colours and motifs, higher is the labour and effort involved and subsequently higher is the product’s value.

Once complete, the fabrics are left to dry in the sun, and then rolled in a newspaper to prevent any undesired imprints caused by excess or bleeding of dyes. The post-printing process sees them being steamed, washed in water, dried in the sun again, and lastly, being ironed.

Modernisation of the Bagru Block Printing and Challenges

While there are quite a few who continue to exclusively use dyes derived from natural sources, the shift towards new types of dyes and colour palettes is a notable change in the cluster. Some contemporary designs don’t involve the use of Rekh or the Gadh but are developed as a beautiful interplay of negative-positive spaces, requiring only the Datta block to be used. While clothing and apparel continue to be drivers of the business, home furnishing items such as block printed quilts, bedspreads, bed sheets and table linen have also become very popular.

Although in the past decade or so, demand for block printing has started increasing, the benefits are yet to trickle down to the artisans, who continue to work under challenging conditions. Such imbalance has forced many of them to switch over to synthetic dyes and machine cut tools, taking away the charm of using natural materials and certain handmade equipment. Endeavouring to change this dynamic, tvami works with small artisans at the grassroots to empower them through their craft while helping them preserve it close to their original form.